Equipment

IMS Engineered Products takes great pride in its value added design review, engineering experience, equipment and craftsmen. We are the industry leader in taking raw materials and processing them into finished products that meet and exceed our customer’s expectations. By utilizing our engineering and manufacturing expertise you will realize higher profitability and shorter product to market time. Check out our video walkthrough of our plant that showcases some of the technology we have on hand.

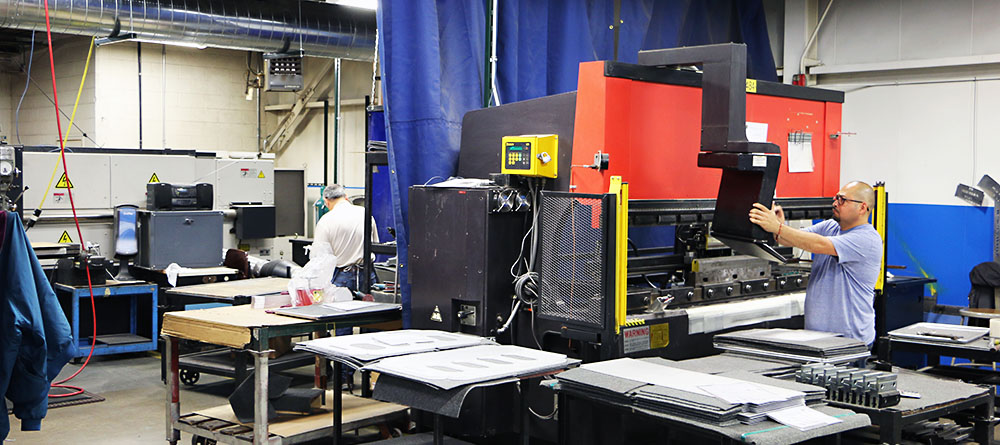

Laser Cutting and Punching

IMS Engineered Products excels at laser cutting, turret punching, shearing and is capable of cutting cold rolled steel up to 1″ thick. Whether you require a prototype or production run, our three lasers and four turrets, assure you that your products will be produced using the best and most cost-effective manufacturing process.

NC Turret Punch Press Department

- (2) Amada NC Turret Press EMK361M, 33 ton, 60” x 120” brush table

(58) Stations with (4) Auto Index Stations - (1) Amada NC Turret Press Vipros 358 King, 50” x 78” Blank Size prior to Repositioning

(58) Stations with (4) Auto Index Stations - (1) Amada NC Turret Press Vipros 255, 50” x 47” Blank Size prior to Repositioning

(31) Stations with (3) Auto Index Stations - (1) Murata NC Turret Press Motorum-2048LT, 49” x 98” Blank Size prior to Repositioning

(54) Stations with (2) Auto Index Stations - (2) Amada Tool Grinding Togu III, NC Turret Tooling Grinders

- (1) Chevalier Tool Grinding Surface Grinder, 6″x12″ Magnetic Chuck

- (1) Boyer-Schultz Tool Grinding Surface Grinder, 6″x12″ Magnetic Chuck

Laser Department

- (1) Amada Laser, Sheet EN3015AJ Fiber 3000 Watt, 60” x 120”

- (1) Amada Laser, Sheet FOMII 3015 NT, 4000 Watt, 60” x 120” with Tower

- (1) Bystronic Laser, Sheet Byspeed 3015, 4400 Watt, 60” x 120” Dual Shuttle Tables

- (1) Mazak Laser, Sheet ST-X44, 1500 Watt, 50”x50” table

- (2) Demag Jib Cranes 2,000 Lb. Capacity

- (1) Anver Sheet Lifter Vacuum Sheet Lifter, 2,000 Lb., 6’ x 10’ Capacity

- (1) Anver Sheet Lifter Vacuum Sheet Lifter, 2,000 Lb., 6’ x 12’ Capacity

- (1) Anver Sheet Lifter Single Pad, Vacuum Lifter, 700 Lb. Capacity

- (1) Bystronic BySmart Fiber 4020; Fiber 10000

MANUAL FABRICATION Department

- (2) Strippit Punching Super 30-30 Fabricators

- (1) Amada Notching CS-220 Corner Notcher

- (1) Built-Rite Rolling Power Roller, 36” Wide Roll, 12 Ga. Mild Steel Max.

- (4) Whitney-Jensen Punching Kick Presses

- (1) Peck & Stowe Shearing Hand Shear, 12” Blade Length

- (1) FlexArm Tapping FlexArm Tapping Machine, 0-80 to 3/8” Tap, 11” to 34” Range

shearing/saw cutting Department

- (2) Cincinnati Shears ¼” Mild Steel, 10 Ft. Capacity with CNC Back Gaging

- (1) Amada Saw Cutting CNC Horizontal Bandsaw, 12” Capacity

- (1) R & M Bridge Crane 10,000 Lb. Capacity, 34’ Wide x 320’ Runway

- (1) Bushman Sheet Lifter 10,000 Lb., 62” Wide Capacity

Forming

IMS Engineered Products’ forming capabilities range from 35 ton all the way up to 500 tons with bed sizes as large as 14′. We also feature an automated Salvagnini bending cell which is a flexible and rapid solution for higher volume products.

Forming Department

- (1) Salvagnini Panel Bender P4-2512, CNC Panel Bender

14 Ga. (.074) Mild Steel Max., 98” Max. Part Length - (1) Cincinnati Press Brake 500 Ton, Hydraulic, 14 Ft., CNC Gaging

- (1) Cincinnati Press Brake 350 Ton, Hydraulic, 14 Ft., CNC Gaging

- (1) Cincinnati Press Brake 230 Ton, Hydraulic, 12 Ft., CNC Gaging

- (2) Cincinnati Press Brakes 230 Ton, Hydraulic, 12 Ft., CNC Gaging

- (2) Amada Press Brake 143 Ton, Hybrid, HG1303, 10 Ft., (8) Axis 2015

- (1) Amada Press Brake 138 Ton, Hydraulic, 10 Ft., Networked, (6) Axis Gaging

- (2) Cincinnati Press Brakes 135 Ton, Hydraulic, 10 Ft., CNC Gaging

- (1) Cincinnati Press Brake 135 Ton, Hydraulic, 8 Ft., Autoform CNC Gaging System

- (1) Accurpress Press Brake 130 Ton, Hydraulic, 10 Ft, (5) Axis Gaging 2015

- (1) Amada Press Brake 110 Ton, Hydraulic, 8 Ft., CNC Gaging

- (4) Amada Press Brakes 100 Ton, Hydraulic, 8 Ft., Networked, (6) Axis Gaging

- (1) Amada Press Brake 88 Ton, Hybrid, HG8025, 8Ft., CNC (8) Axes 2015

- (1) Amada Press Brake 88 Ton, Hybrid, HG8025, 8Ft., CNC (8) Axes 2016

- (1) Amada Press Brake 88 Ton, Hybrid, HG8025, 8Ft., CNC (8) Axes 2017

- (1) Amada Press Brake 80 Ton, Hydraulic, 8 Ft., Networked, (6) Axis Gaging

- (1) Amada Press Brake 35 Ton, Hydraulic, 4 Ft., Networked, (6) Axis Gaging

Stamping

IMS Engineered Products’ stamping capabilities range from 45 to 220 tons with three different size beds for stamping.

Stamping Department

- (1) Aida Punch Press 220 Ton, Gap Frame, W/Cushion, 95” x 33” Bed Size

9.8” Stroke, 19.6” Shut Height - (1) Bliss Punch Press 60 Ton, OBI, W/Cushion, 24” x 20” Bed Size

4” Stroke, 14.25” Shut Height

Welding

IMS Engineered Products specializes in welding steel, aluminum and stainless steel. Our skilled craftsman, quality machines and extensive experience with different materials make us an industry leader.

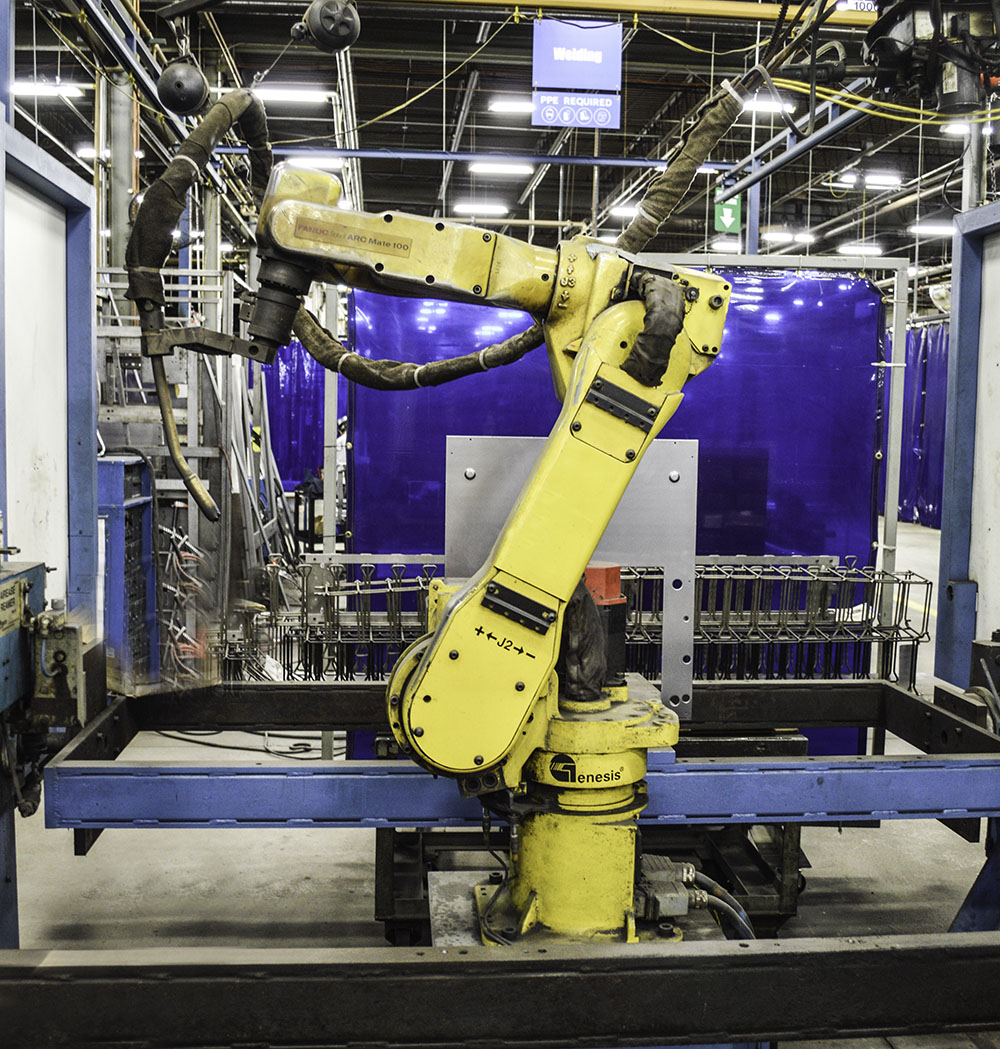

Robotic Welding Cell

- (1) Fanuc Robot RJ2 Arc Mate 100, 6 Axis CNC Welding Robot

- (1) Lincoln Mig Welder Power Wave 450 Welding Power Source

- (2) Fanuc Rotary Index 36” x 82” Programmable Rotary Index Positioners

Manual Welding Operations

- (4) Miller TIG Welding 351 Synchrowave Heliarc Welders

- (4) Miller TIG Welding 350 Synchrowave Heliarc Welders

- (5) Miller TIG Welding 300 Synchrowave Heliarc Welders

- (1) Miller TIG Welding 300 Synchrowave Heliarc Welder with Pulse Option

- (4) Miller TIG Welding 250DX Synchrowave Heliarc Welders with Pulse Option

- (2) Miller MIG Welding CP302 MIG Welders, 375 Amp

- (1) Miller MIG Welding MP250 MIG Welder, 250 Amp

- (4) Miller MIG Welding Millermatic 200, MIG Welders with Pulse Option

- (1) Hypertherm Powermax 30 Plasma Cutter

- (2) Gorbel Bridge Crane 1 Ton Bridge Cranes, 15’ Wide x 23’ Runway

Spotwelding

- (2) Peer Spotwelding 150 KVA Piston Style Spotwelder

- (1) Federal Spotwelding 100 KVA Rocker Arm Style Spotwelder

- (5) Acme Spotwelding 100 KVA Vertical Suspension Style Spotwelders

- (1) Seedorf Spotwelding 75 KVA Piston Style Spotwelder

- (1) Acme Spotwelding 75 KVA Rocker Arm Style Spotwelder

- (1) Lors Spotwelding 75 KVA Piston Style Spotwelder

- (2) Banner Spotwelding 50 KVA Piston Style Spotwelders

- (1) Peer Spotwelding 50 KVA Piston Style Spotwelder

- (1) Peer Spotwelding 50 KVA Rocker Arm Style Spotwelder

- (2) Banner Spotwelding 30 KVA Piston Style Spotwelders

- (1) Acme Spotwelding 30 KVA Piston Style Spotwelder

- (2) Various Mfg. Spotwelding 15 KVA Rocker Arm Style Spotwelders

Automation

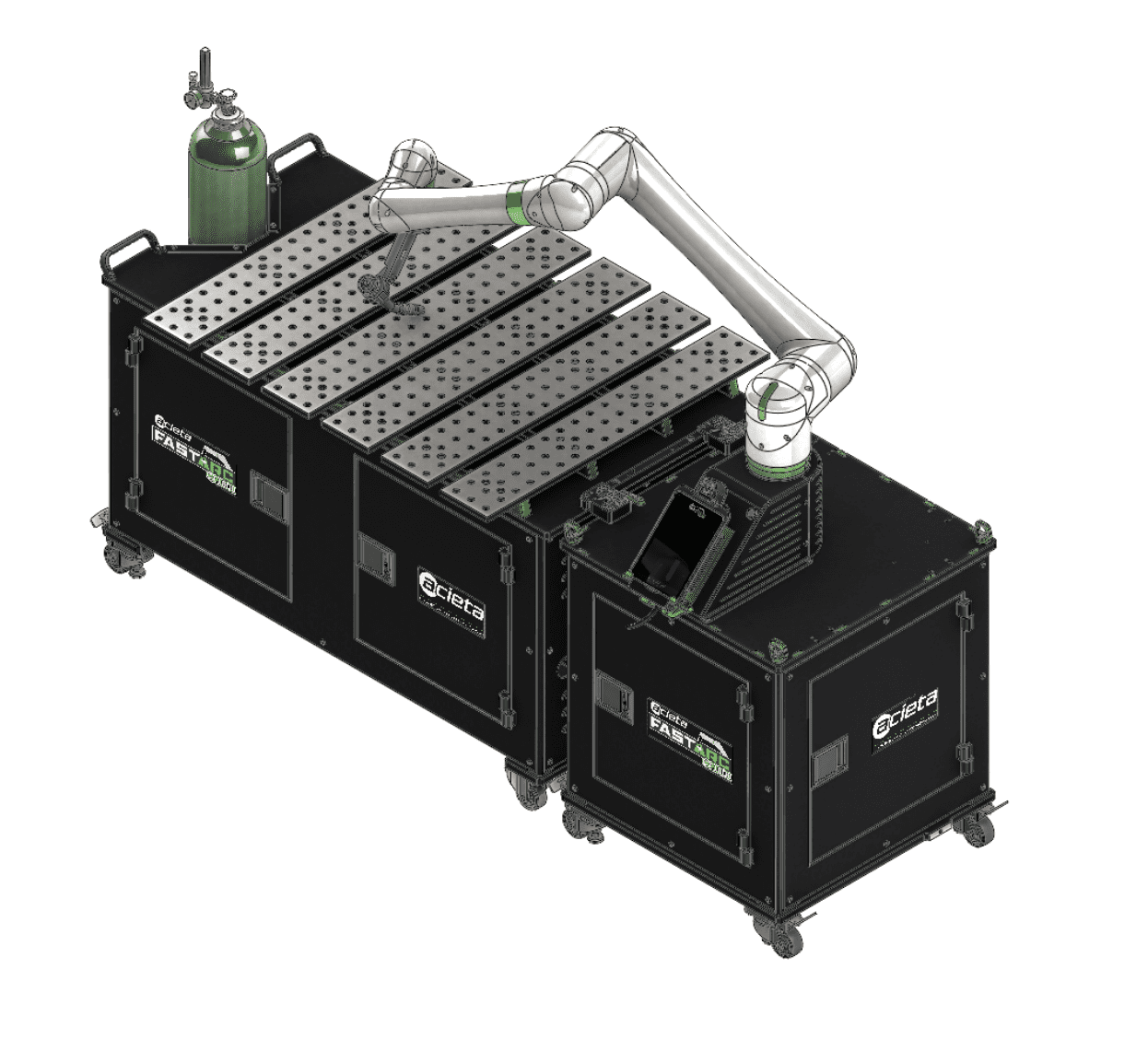

IMS Engineered Products offers an array of automation machines including a cart-mounted welding cobot and our 3 piece Trumpf cells.

Cobot Welder

- (1) Acieta FastARC CX1000 – cart-mounted cobot

Trumpf

- (1) TruPunch 5000

- (1) TruStore 3030

- (1) TruBend Center 7030

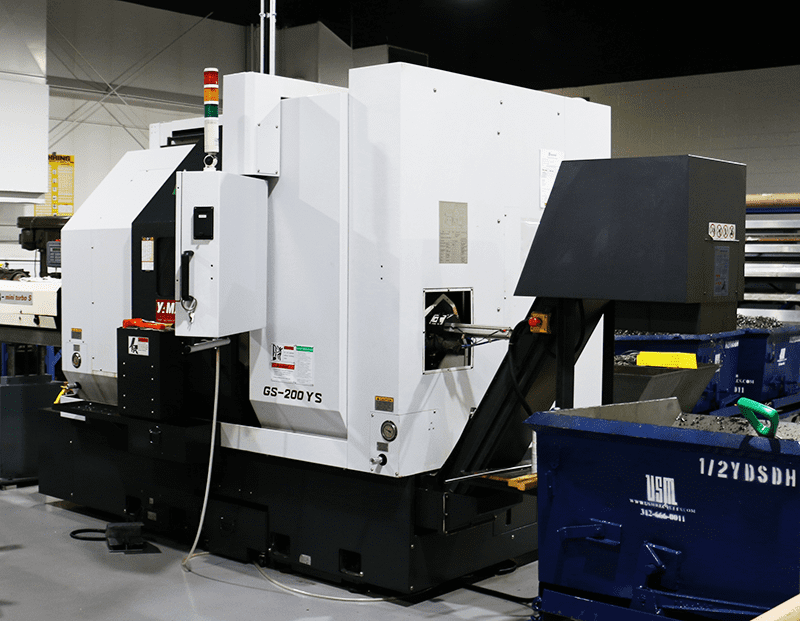

Machining

IMS Engineered Products offers a full array of CNC machining including CNC Horizontal and Vertical Machining Centers, CNC Turning and Swiss Turning Centers, along with other various machining equipment.

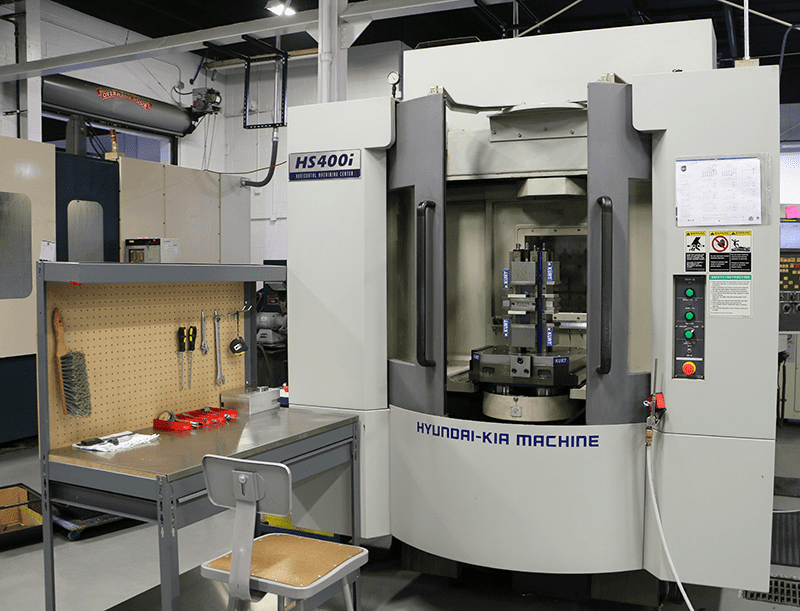

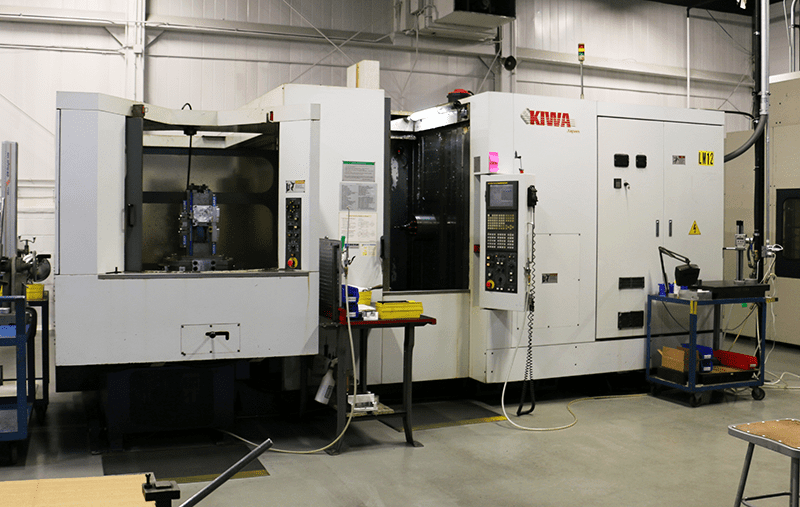

CNC HORIZONTAL MACHINING CENTERS

- (1) Kiwa 426X, Travels X=24” Y=24” Z=26”, 400 mm pallets, 12000 rpm, 35 hp, 120 tools, pallet pool with 6 pallets with an additional 2 pallets

- (1) Mitsubishi M-H4B, Travels X=26” Y=22” Z=26”, 400 mm pallets, 12000 rpm, 30 hp, 60 tools, dual pallet changer with 2 extra pallets

- (1) Mitsubishi M-H4B, Travels X=26” Y=22” Z=26”, 400 mm pallets, 12000 rpm, 30 hp, 40 tools, dual pallet changer

- (1) Hyundai-Kia HS400i, Travels X=24.4” Y=22” Z=25.6”, 400mm pallets, 12000 rpm, 30 hp, 60 tools, dual pallet changer with 4 extra pallets

CNC VERTICAL MACHINING CENTERS

- (1) Leadwell V60, Travels X=60” Y=30” Z=30”, 10000 rpm, 30 hp, 30 tools

- (1) Takumi V10N, Travels X=40” Y=24” Z=24”, 10000 rpm, 20 hp, 24 tools

- (1) Chevalier 2040MV-L, Travels X=40” Y=20” Z=23”, 8000 rpm, 15 hp, 24 tools

- (1) Kiwa Triple V-21, Travels X=22”, Y=16”, Z=18”, 12000 rpm, 10 hp, 24 tools, rotary pallet changer

- (5) Kitamura Mycenter 1’s, Travels X=20” Y=13” Z=16”, 13000 rpm, 7.5 hp, 20 tools

- (1) Haas VF4 SS, Travels X=50” Y=20” Z=25” 12,000 rpm, 30 hp, 30+1 tools with a TRT 210 5th axis rotary table

- (1) Haas VF6 SS, Travels X=64” Y=32” Z=30” 12,000 rpm, 30 hp, 30+1 tools

CNC TURNING CENTERS

- (1) Yama Seiki GS-200YS, 8” chuck or Quick Grip 42mm collet main spindle, 6” chuck or 16c collet subspindle, 12 station turret with live tools and Y-axis, C-axis on main and sub, magazine bar loader

- (1) Daewoo Puma 6HS, 6” chuck or 5C/16C collet, max dia. 8.5”, distance between centers 15”, 6000 rpm, 20 hp, 12 station turret

CNC SWISS TURNING CENTERS

- (1) Citizen M32 III, 1.26” bar capacity, max part length 12.8”, 8000 rpm, up to 16 live tools, full C axis on main and sub spindle, magazine bar loader

- (1) Citizen L20 VIII, 0.787” bar capacity, max part length 8.0”, 10000 rpm, 7 live tools, full C axis on main and sub spindle, magazine bar loader

COORDINATE MEASURING MACHINE

- (1) WENZEL 8.15.7, DCC, OPENDmis software, work cube X=32” Y=59” Z=28”

INSPECTION EQUIPMENT

- (4) Fowler Trimos digital height gages

- (1) OGP OQ-20 optical comparator

- (1) OGP Top Bench 14” comparator – wide assortment of gauging

CNC PROGRAMMING

- GIBBSCAM V11.3.10 with solid surfacer

NC AND MANUAL EQUIPMENT

- (1) Daito GA260 nc cutoff band saw

- (1) Mitsui Seiki 8” X 18” surface grinder with Sony dro.

- (2) Harig 612 surface grinders

- (2) Sunnen MBB-1650 hone’s

- (1) Christen drill grinder, 1/32” to 1 ¼” capacity – manual lathes, band saws, grinders, toolroom equipment

Finishing

IMS Engineered Products can provide you with a variety of quality cosmetic finishes. Our state-of-the-art powder coat and wet coat paint line can provide you with the exact color and coating that you require. Our polishing department is capable of various cosmetic finishes.

Stainless Steel Polishing Department

- (1) Butfering Deburring Wide Belt Sander, 37” Belt Width

- (1) Butfering Deburring Wide Belt Sander, 52” Belt Width

- (1) Loewer DiscMaster Deburring Multi head model 4TD-1000 edge finisher 2015

- (1) G & P Stroke Sanding 8 Ft. Capacity

- (2) G & P Stroke Sanding 6 Ft. Capacity

- (1) Beech Stroke Sanding 8 Ft. Capacity

- (2) G & P Belt Sanding 4” Belt Sander, Dual Head

- (1) L’Hommedieu 3M Deburring 3M Deburring Lathe, Dual Head

- (1) Hammond Deburring Roto-Finish, 20 Cu. Ft. Vibratory Tumbler

- (1) Ultramatic Deburring Vibratory Tumbler

- (1) Pauli & Griffin Media Blaster 60” W x 48” D x 33-1/2” H, Pressure Type Blast Cabinet

- (1) Cyclone Media Blaster 48” W x 26” D x 22” H, Siphon Type Blast Cabinet

- (2) Falls Prod’s Deburring Edge Deburring Machines

Full Array of Manual, Air and Electric Power Hand Deburring, Grinding and Polishing Tools.

HARDWARE/ASSEMBLY DEPARTMENT

- (3) Haeger Clinch Hardware Hardware Insertion Presses, Autofeed W/Shuttle Tooling

- (1) Haeger Clinch Hardware Hardware Insertion Press, Autofeed

- (3) Haeger Clinch Hardware Hardware Insertion Presses, Manual Feed

- (2) Nelson Stud Welding Nelson Style Stud Welding Guns

- (2) Riv-Nut Riv-Nut Riv-Nut Installation Guns

- (2) Avdel Rivet Avdel Rivet Installation Guns

- (3) Pop Rivet Pop Rivet Installation Guns

- (1) EFD Fluid Dispensing Air-Powered Fluid Dispenser, Adhesives, Epoxies, Sealants, etc.Full Array of Manual, Air and Electric Tools for Assembly, i.e.: Ratchets, Screw and Nut Drivers, etc.

TOOLING/MACHINING DEPARTMENT

- (1) Certa Craft CNC Machining Center

- (1) Hardinge Super Precision Lathe

- (1) Cadillac Lathe

- (2) Various Mfg. Bridgeport Style Milling Machines

- (1) American Radial Drill Press

- (1) Various Mfg. Surface Grinders, with Magnetic Chucks

- (1) Okamoto Wet Surface Grinders, 16” x 31” Magnetic Chucks

- (1) Dake Vertical Band Saw

- (4) Haberle Cold Saws

- (1) Kysor Johnson Horizontal Band Saw

- (1) Ramco Horizontal Band Saw

- (5) Various Mfg. Multi-Head Gang Drills

- (1) Cincinnati Arbor Mill

- (2) Various Mfg. Clausing/Commander Head Fitted Drill Presses

- (15) Walker Turner Drill Presses

- (1) Darex Drill Sharpener

- (1) Budget 2 Ton Hoist

- (1) Ram-Pac 30 Ton Hydraulic Press

- (1) Carolina 10 Ton Hydraulic Press

- (1) Famco 4 Ton Arbor Press

Powder/Wet Coat Painting Department

- Midwest Finishing Systems, Powder Coating and Water Based Liquid Paint Line with:

- (5) Stage Washer

- (7) Minute Dry Off Oven

- (25) Minute Cure Oven

- (2) Nordson Powder Coating Booths

- (3) Col-Met Water Based Liquid Spray Booths

- (1) Infrared Flash Off Oven

- (1) Col-Met Batch Spray Booth, Powder and Water Based Liquid Paints, 140″ Wide x 96″ High with:

- (1) Burdett Batch Oven with a 65″ Wide x 94″ High x 132″ Deep Maximum Part Envelope

- (1) Burdett Batch Oven with a 72″ Wide x 90″ High x 108″ Deep Maximum Part Envelope

Silkscreen Department

- Silkscreen/Screenprinting Department with Full Screenprinting Capabilities

Prototyping

IMS Engineered Products features a dedicated prototype and short-run department staffed with highly experienced craftsmen. Our prototype department can assist with all of your quick term requirements and will work with our engineering team to offer DFM recommendations. Design and production of short-run tooling is also done in house. IMS EP also offers a manufacturing fast track program for any short-run parts that exceed the equipment capabilities of our prototype department.

Quality

IMS Engineered Products’ top priority is our quality with practices being in accordance with ISO 9001:2015. Our quality is built into new product development all the way through full production. Calibrated equipment, testing systems and in-process controls are just a few of the quality components.

Inspection Department

- (1) Virtek FabriVision Laser QC Rapid InspectionSystem

- (1) Romer CMM Arm 6’

- (1) Hansford CMM, 36” x 96” Envelope

- (3) Various Mfg. Granite Surface Plates, 36” x 48”

- (5) Various Mfg. Granite Surface Plates, 18” x 24”

- (1) Nikon Optical Comparator, 16” Screen Dia. with Digital Readout

- (1) Rockwell Hardness Tester

- (1) Wilson Hardness Tester

- (1) Chatillon Digital Force Gauge

- (2) Macbeth Spectrophotometer, Color Measurement Testers

- (2) Various Mfg. Gloss Meters

- (3) Various Mfg. Coating Thickness Testers

- (1) Gardco Pencil Hardness Tester

- (1) Gardco Paint Adhesion Tester

- (1) Gardner Gravity Impact Tester

- (1) Dillon Dynamometer Tensile Tester, 0-6,000 Lb.

Full Complement of Hand Measuring Devices, i.e.: Digital Height Gages, Pin Gages, Digital and Dial Calipers, Micrometers, Dial Indicators, Thread Gages, Counter Sink Gages, Protractors, Torque Wrenches, etc.

To view our ISO 9001 certification and Quality policy, click on the buttons below.